Our decoration machines

Burnishing

The new AR20 burnishing machine is equipped with a new modular loading system, a new highly precise CNC PLC and a digital positioning assistance for more comfort during set-up and use.

The four CNC axes operate simultaneously up to twenty-four seats (twelve seats per side). The burnishing operation can be used for mechanical (part hardening) but also for cosmetic purposes (improvement of the visual surface aspect).

The part reference socket is carried out in "touching" mode, which saves a significant amount of time during set-up.

Burnishing | Hardening | Surface Finish | Pinions

Precision 1 μm | CNC

Modular Loading | Automatic | Manual

Vibrating Bowl | Wahli W20 Charger

Circling Machine

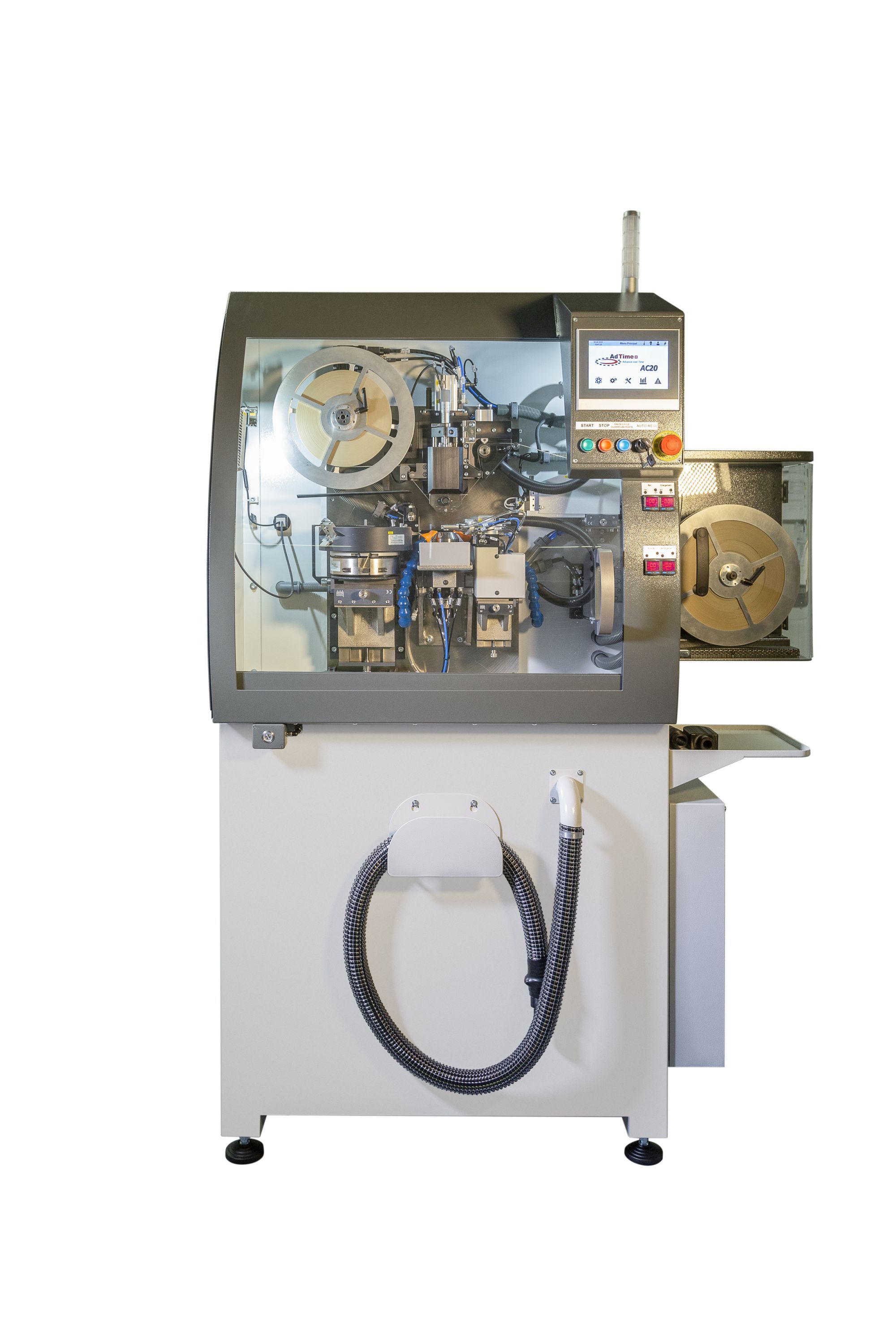

The AC20 circling machine allows the automatic and precise circling of both sides of a wheel. It is possible to circle both solid or arm wheels, cut or uncut.

Highly reliable, the AC20 circling machine has an automatic mechanism for loading, turning and unloading parts. This makes it possible to maintain high production rates, a great repeatability and a very qualitative decoration.

Circling | Automatic | Manual | 1 Side | 2 Sides

Solid Wheels | Arm Wheels | Cut Wheels | Uncut Wheels

Offset Circling | Vacuum | Cleaning

Notching Machine

Our notching machines allow the automatic and precise sinking of both sides of a wheel. As for the AC20 circling machine, it is possible to circle both solid or arm wheels, cut or uncut.

Highly reliable, our nochting machines have an automatic mechanism for loading, turning and unloading parts. This makes it possible to maintain high production rates, a great repeatability and a very qualitative decoration.

As a 2024 innovation, the AM20 notching machine is the new compact version (machine on an ergonomic workbench).

Notching | Sinking | Automatic | Manual | 1 Side | 2 Sides

Solid Wheels | Arm Wheels | Cut Wheels | Uncut Wheels

Vacuum | Cleaning

Compact Machine | Ergonomic Workbench

Other Decorations

AdTime also has extensive experience in multiple other decorating operations, semi-automatically and automatically, such as:

We will be happy to develop a product à la carte for you. Do not hesitate to contact us for more information on the different machine options to carry out your decorating operations. We are happy to offer you a non-binding offer for the machine matching your needs the best.

Oscillating Weights | Spiral | Sunshine | Straight

Lines

Automatic | Semi-Automatic | Manual

Vacuum | Cleaning

Compact Machine | Ergonomic Bench

AdTime - Rue des Artisans 4 - 2830 Courrendlin - +41 (0) 32 435 19 91 - info@adtime.ch